|

|

|

|

#1 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

Swingarm / Shaft Service

Picked up a 2004 Nomad with 10k miles this fall. I'm very nervously doing the swingarm service, after reading all of this forum.

This is what I found for grease:  Forgot the grease! by Jon, on Flickr Forgot the grease! by Jon, on FlickrIs this the combination seal and thrust washer?  Seal? by Jon, on Flickr Seal? by Jon, on FlickrThe u-joint seems to be stiff in one plane. In one, I can just flip it over and the joint flops down. In the other, it takes maybe 4-8 lbs of pressure to move it, as measured by my bathroom scale calibrated thumb! What do you think, should I order the 4-wheeler replacement? Click for video, for what it's worth!  U Joint by Jon, on Flickr U Joint by Jon, on FlickrThank you in advance and for this great forum! Jon

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! Login or Register to Remove Ads |

|

|

|

#2 |

|

Top Contributor

Join Date: Feb 2008

Location: Ontario

Posts: 6,926

|

It appears that is the seal/thrust washer you are pointing to.

The bike is pretty low mileage (10,000 miles) to have the U Joint go bad but if you are concerned about it now is the time to replace it. As usual the gears, and needle rollers in the swing arm are bone dry from the factory. |

|

|

|

#3 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

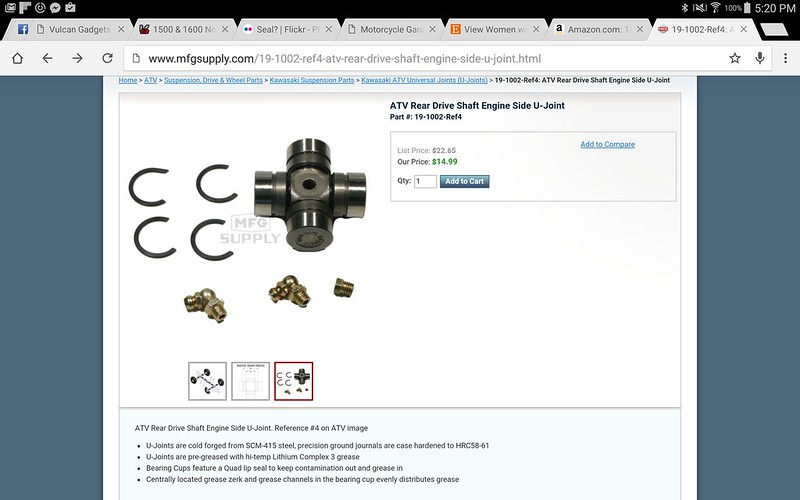

So, after further review I have ordered this:

I sure hope I can get it installed without a lot of drama!

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! |

|

|

|

#4 |

|

Top Contributor

Join Date: Feb 2008

Location: Ontario

Posts: 6,926

|

The trick with any universal joint is to grease the needle rollers well so they don't fall over during the install. Lots of grease will help to prevent that during the assembly.

|

|

|

|

#5 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

Thanks, Redjay! Never had one apart, so I'm not sure what I'm in for. Gadget's write-up makes it seem doable. I was reluctant to do that swingarm service, but so far so good. Looks like it was needed, with that grease shortage. Now if i can just get it back together...

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! Login or Register to Remove Ads |

|

|

|

#6 |

Join Date: May 2009

Location: Greenwood, Ark.

Posts: 4,736

|

If got it apart you can get it back together.

I think you have the right idea replacing the u-joints. They should move freely in any direction. If they were to seize up at highway speed it could end badly.

__________________

Dave Jesse 2012 1700 Gray/Black Voyager 2006 1600 Nomad Green/Silver Sold VBA #1108 2010- Eureka Springs - Antlers - 2011- Maggie Valley - Antlers 2012- Margaritaville Ride - Van Buren - Antlers - 2013- Estes Park - Antlers 2014- Mountain View - Antlers - 2015- Eureka Springs - Antlers 2016- Salem - Antlers - 2017- Eureka Springs - Lake George - Antlers - 2018- Custer - Antlers |

|

|

|

#7 |

Join Date: May 2009

Location: Montreal QC

Posts: 12,034

|

Agree on changing the u joint. It should move the same in both planes. You may not be noticing it at this point but it is most likely causing a slight viberation or oscillating noise as the suspension works. The bike will feel that much smoother when it is changed, not to mention piece of mind from a future failure.

__________________

Norm Ward 2008 blue / silver nomad kawanow / VBA #01136 |

|

|

|

#8 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

I'm with you there, men! Especially the piece of mind aspect. But, it would be nice to get a piece of that legendary Vulcan buttery smoothness that so far I have only read about. The ride wasn't bad by any means, but there was a little vibration so I think you may be on to something.

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! |

|

|

|

#9 |

|

Sr. Member

Join Date: Jan 2008

Location: Cartersville, Georgia

Posts: 4,838

|

A V-Twin is not going to be as smooth as a Goldwing, but for a V-Twin, the Nomad is a very smooth machine, noisy, but smooth. The first time I serviced my swing arm, I found the same as you. I disassembled the U-joint and found very little grease. I emptied the 4 cups of needle bearings, cleaned everything good in a parts washer, then reassembled all the old parts using that Honda 60 Moly-Lube. It didn't flop in either plane, but took ever so slight of a shake to get it to move in both planes (new grease), and 60,000 miles later, when I did the last inspection, It was still good.

On occasion, mine will develop a vibration when accelerating, and I have found the cause of mine is the "slip joint is dry (what connects the shaft to the final drive). I re-grease the splines and put 20 ml of grease down in the slip joint (as per manual), then reassemble. This has always taken care of the vibration.

__________________

Cliff "VulcanE" Evans 2005 Blue & Silver 1600 Nomad VBA # 320 VROC # 20381 |

|

|

|

#10 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

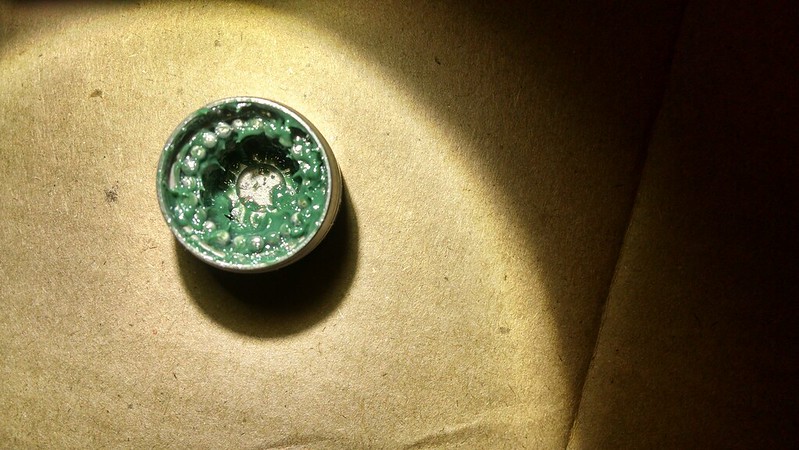

Thanks, Cliff. Wish I had read that before I used Lucas X-tra heavy duty grease. I had read not to use Moly on them! It was quite a fight to get the joint apart, but I finally did. Surprised me that there were no grooves in the cap for all those needles.

Should I put more grease than this? I'm guessing yes.  Ujoint bearings by Jon, on Flickr Ujoint bearings by Jon, on FlickrIt turned out to be easier than I anticipated to put the needles in. I used a small, slightly magnetized screwdriver to pick up the needle hanging vertically. I then put the bottom of the needle in and pulled the top back to the cap. The grease overpowered the magnetism and the screwdriver released. Is there a better way, before I get after the other 3? Thank you all for the help! Jon

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! |

|

|

|

#11 |

|

Top Contributor

Join Date: Feb 2008

Location: Ontario

Posts: 6,926

|

That looks like plenty of grease. What you don't want is for one of the rollers to fall into the bottom of the cup.

|

|

|

|

#12 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

Thanks! I'm hoping that the seal will hold things together a little. One down...

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! |

|

|

|

#13 |

|

Sr. Member

Join Date: Jan 2008

Location: Cartersville, Georgia

Posts: 4,838

|

That looks good, any excess will be forced out when you put it together, and like redjay said, make darn sure one of the rollers don't fall over when putting it back together. Also make sure you do them one at a time, and use all the rollers, you don't want any left over. That Honda 60 Moly-Lube was designed especially for the needle bearings in U-joints, and it has held up well for me.

__________________

Cliff "VulcanE" Evans 2005 Blue & Silver 1600 Nomad VBA # 320 VROC # 20381 |

|

|

|

#14 |

|

Jr. Member

Join Date: Oct 2015

Location: Harrisville, NY

Posts: 28

|

Think I found the source of the stiffness!

Carnage by Jon, on Flickr Carnage by Jon, on FlickrYou can see the nice grooves at the top of the cap. The bad news: The bearings flew out of one cap when I pulled it. I thought I got them all, came up with 22. The one pictured has 22.5! It seems just about impossible to find a small quantity of 2 x 9.5 mm needles. I did find some 2 x 15 mm. Do you think it would be okay to grind a couple to length? I haven't disassembled any of the other caps, but I'm assuming that I will find 23 needles in them. The good news: I found a used complete shaft on ebay for 25 bucks shipped! It's off a 50k mile bike, so I will probably rebuild it anyhow, but at least I know I'll have all the parts. SO... Would you grind the bearings and use the new joint (with zerk), throw in the used shaft, or steal some bearings from the used one and install the new one? As always, thank you for the help!

__________________

VBA #03234 2004 Nomad 1500 FI, The fastest color! |

|

|

|

#15 |

|

Top Contributor

Join Date: Feb 2008

Location: Ontario

Posts: 6,926

|

Why not buy the U Joint kit as shown in post #3 and install that ?

|

|